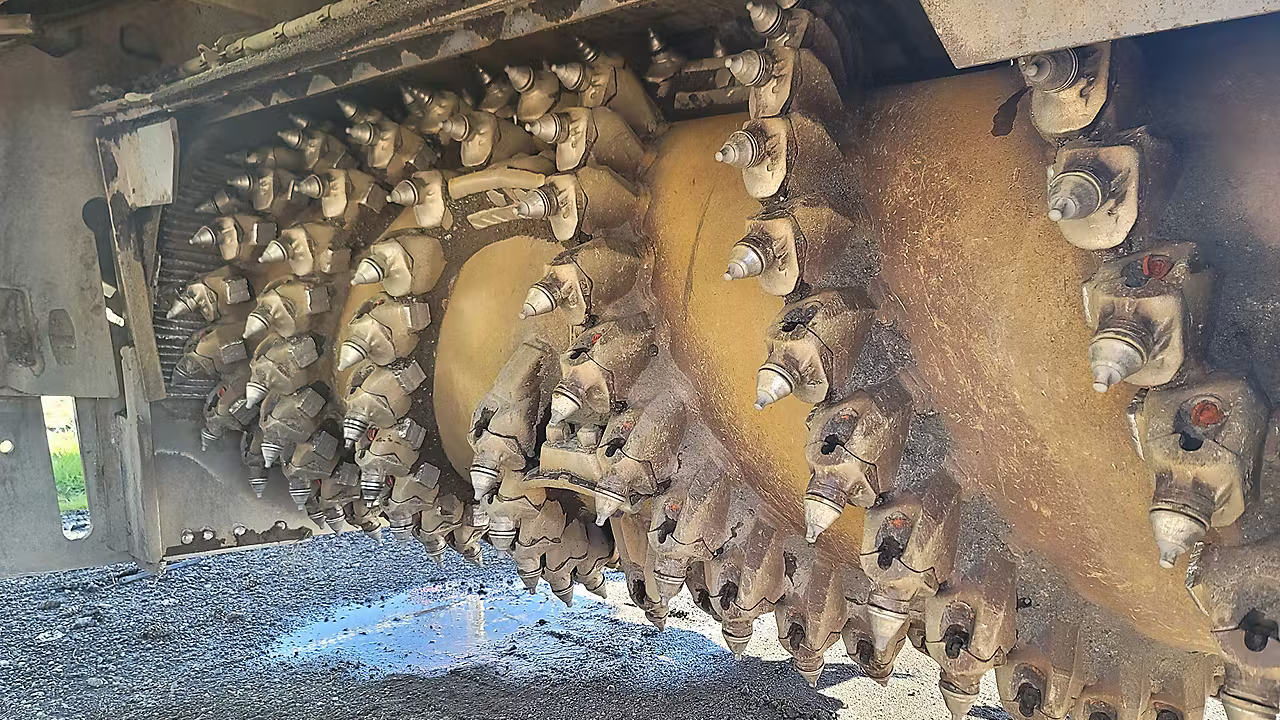

Milling teeth quality directly affects both operational performance and the operational lifespan of milling operations. The harsh operating environment of these components led to improved performance after wear-resistant coatings were applied since they increased service duration and reduced operational expenses. The research examines contemporary protective coatings that safeguard road milling machine teeth in use.

Importance of Wear-Resistant Coatings

Wear-resistant coatings prolong the long-term operation of milling teeth since they reduce friction and block corrosion while enhancing their cutting efficiency. The absence of suitable protective measures on milling teeth leads to rapid deterioration that requires more frequent replacements and increases operational expenses.

Advanced Coating Technologies

Research in present times explores novel materials alongside different techniques to enhance the lifespan of milling teeth. The most effective coating procedures include:

Tungsten Carbide Coatings

Tungsten carbide proves to be a widely implemented material for wear-resistant coatings because it maintains high hardness levels and shows outstanding resistance to abrasion. The application of high-velocity oxygen fuel (HVOF) spraying techniques produces longer-lasting tungsten carbide coating performances.

Diamond-Like Carbon (DLC) Coatings

DLC coatings provide optimal performance for milling teeth operating under harsh conditions because they offer outstanding hardness and reduced friction. The contemporary coating technology fights against material buildup, which allows machinery to maintain precise cutting capacity for increased operational periods.

Ceramic-Based Coatings

The rising market demand for ceramic coatings is well known. This is because it offers outstanding heat resistance and enhanced hardness properties. Tools with protective layers become resistant to heat encountered in milling operations, helping them maintain their quality without premature failure.

Titanium-Based Coatings

Industrial applications of titanium Nitride (TiN) and titanium Carbonitride (TiCN) benefit from their superior defense against wear and oxidation effects. The production methodology of these coatings creates reduced friction and better cutting performance that leads to extended tool operational duration.

Benefits of Wear-Resistant Coatings

Several advantages emerge from using innovative coatings on milling teeth because they offer:

- The lifespan of coated milling teeth extends beyond uncoated alternatives, which decreases the need for tool replacements.

- Better cutting performance becomes possible through the combination of lower friction and greater hardness, which enables productive scaling operations.

- Maintaining tools within these coatings results in decreased maintenance costs, together with decreased downtime.

- The decreased power requirements from reduced wear and friction lead to lower fuel consumption in milling operations.

- Modern coating technology helps milling teeth resist harsh environmental conditions such as extreme temperatures, oxidation as well as corrosion through protection.

Future Trends in Wear-Resistant Coatings

Users of wear-resistant coatings within road milling will concentrate on developing better performance alongside sustainable solutions for the future. Some emerging trends include:

- Nano-coatings present several benefits through their nanostructured structures to create superiorly hard and resilient manufacturing components for milling teeth applications.

- Scientists work to develop self-regenerative coatings that fix small surface flaws to improve milling teeth ' life expectancy.

- The industry now implements environmentally beneficial coating techniques that produce less waste materials while decreasing emissions levels.

Conclusion

Modern wear-resistant coating technologies applied to road milling machine teeth deliver improved operational capabilities as well as productivity, longer service life, and better price efficiency. The application of tungsten carbide and titanium-based DLC and ceramic coatings on milling teeth enables their operation in harsh environments, which leads to better road milling efficiency. The development of self-healing materials along with nano-coatings through technological progress will enhance the sustainability of milling teeth.